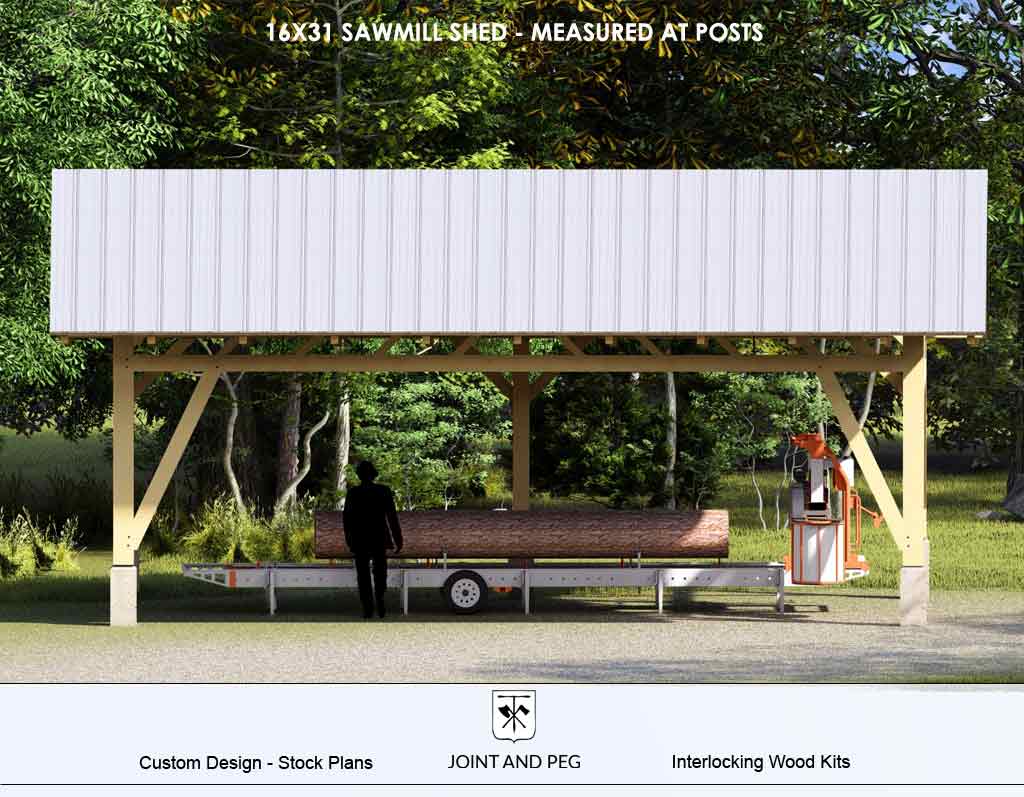

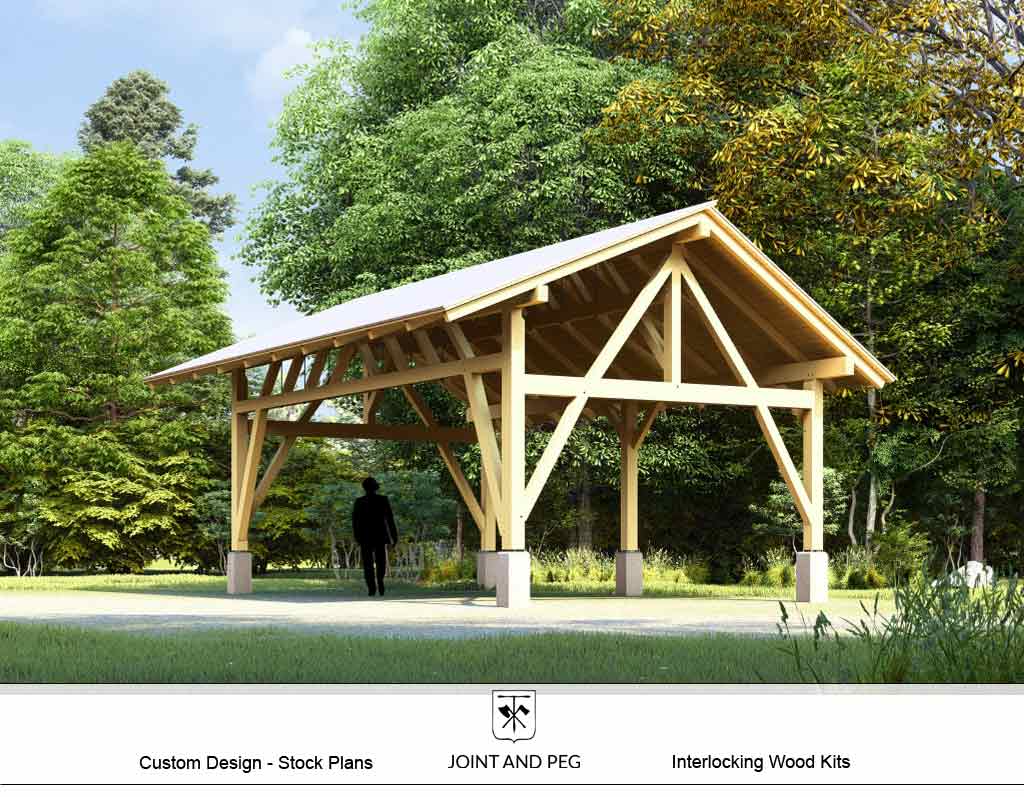

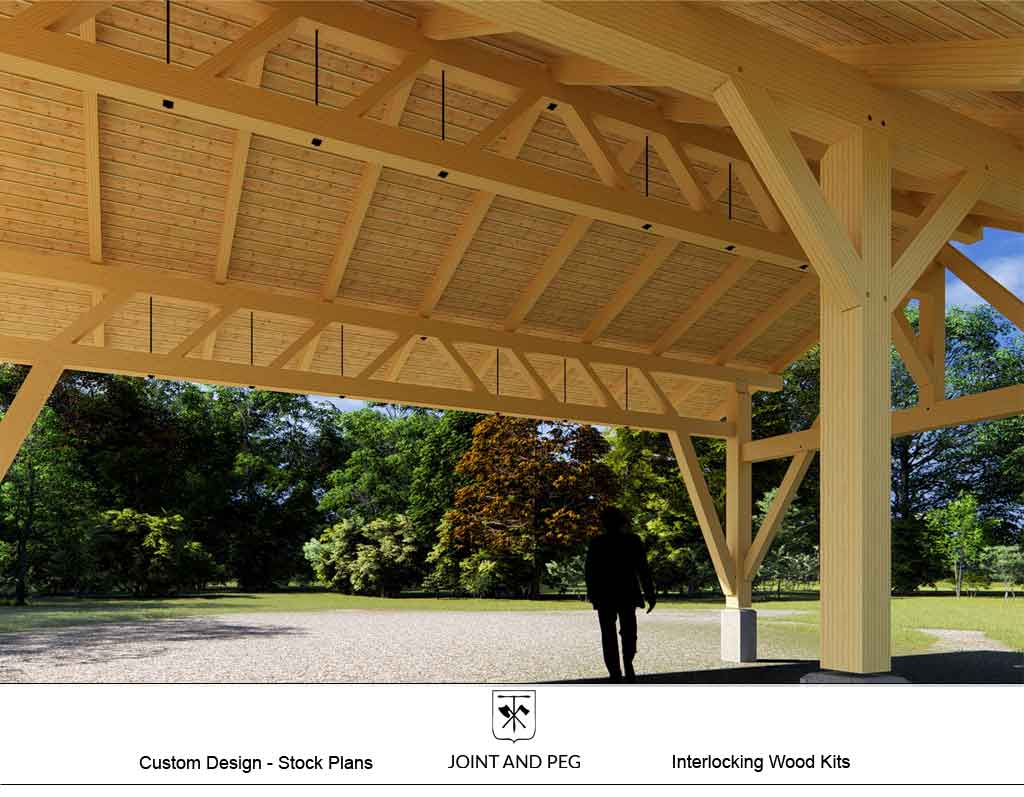

Are you looking for a strong timber frame to protect your sawmill? This 16×31 Sawmill Shed Plan delivers. Not only will you get a structure that is designed to perform in areas up to 30psf snow loads, but you will also get the best-looking sawmill shed available. You can certainly show that you mean business when you put your sawmill under this timber frame structure.

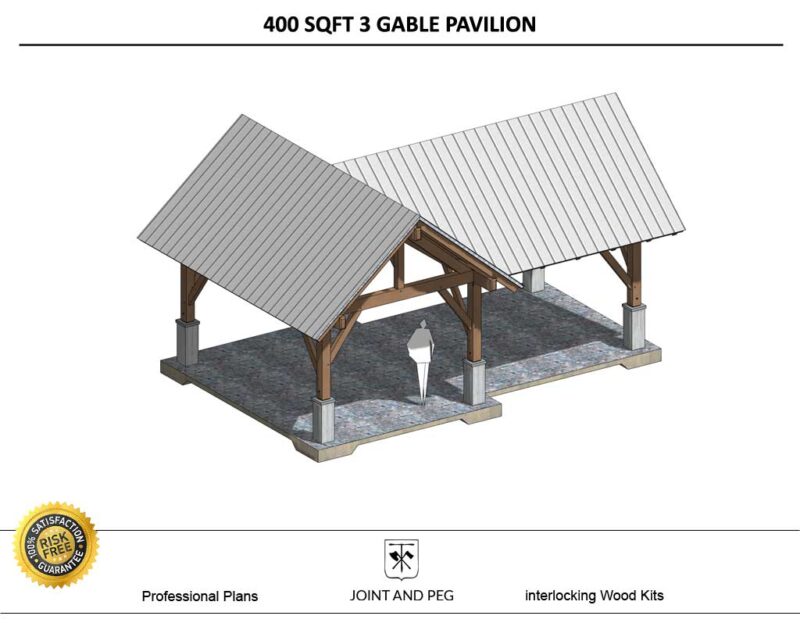

Although we have a sawmill in mind, this open-air structure would also work great as a band stand, pool house, outdoor material storage shed.

Lots of clear space and protection from weather.

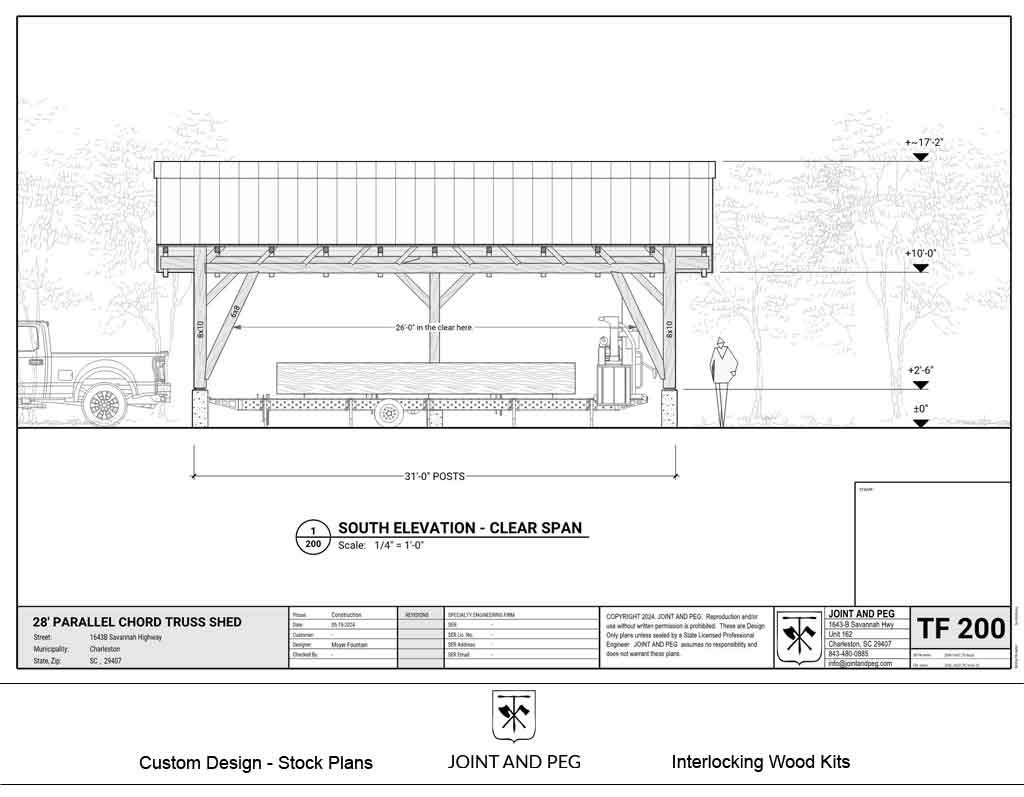

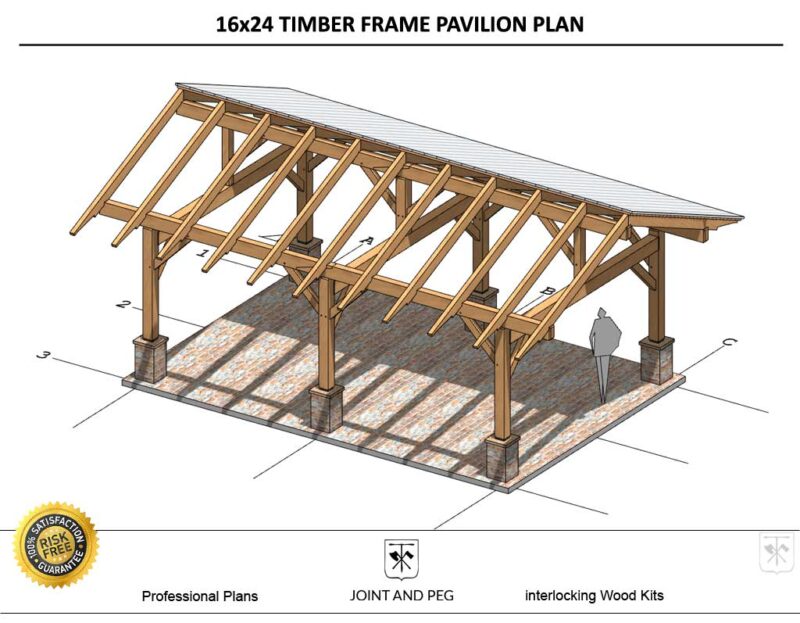

This timber frame structure consists of 5 posts and measures out at the posts at 16’x 31’ outside to outside. The eave with (2) posts provides a clear span of 28’ at head height. Unlike most sawmill sheds this design has a gable roof and provides a 4 foot overhang on the high clear span eave and a 2’ overhang on the low eave. This roof gives you a realized protected square footage of roughly 22’x35’! All the while, not letting rain come in on your mill like shed roof structures do. Protect your investment covered below this awesome timber frame sawmill shed.

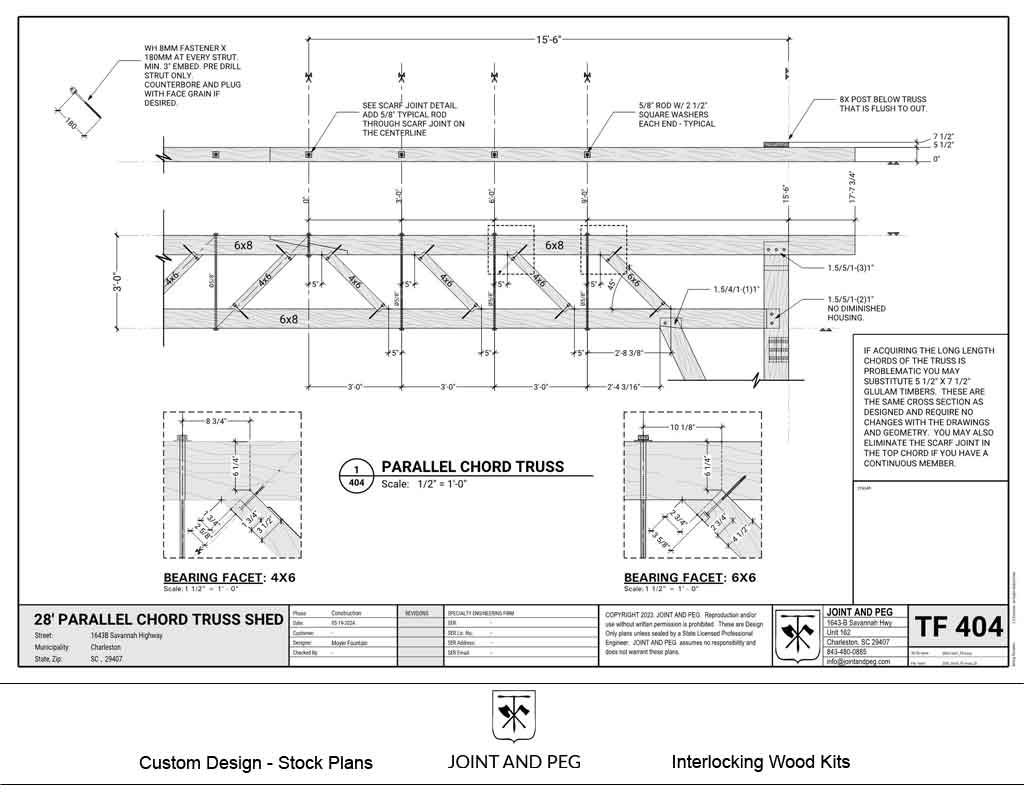

29’ Clear span parallel chord truss.

What good is a sawmill shed if you can’t bring a log in from the side? This design and plan includes an elegant, but strong, parallel chord truss of timber with iron tie rods. We happen to like the 5/8” diameter rods that resolve the forces in the truss. It’s a perfect balance of timber and iron. The truss and the rest of the structure has been designed to withstand up to 30lbs of ground snow load allowing it be a good option for most of the USA. We do not recommend this design for alpine, seismic, or hurricane areas (unless reinforced for wind loads in hurricane areas).

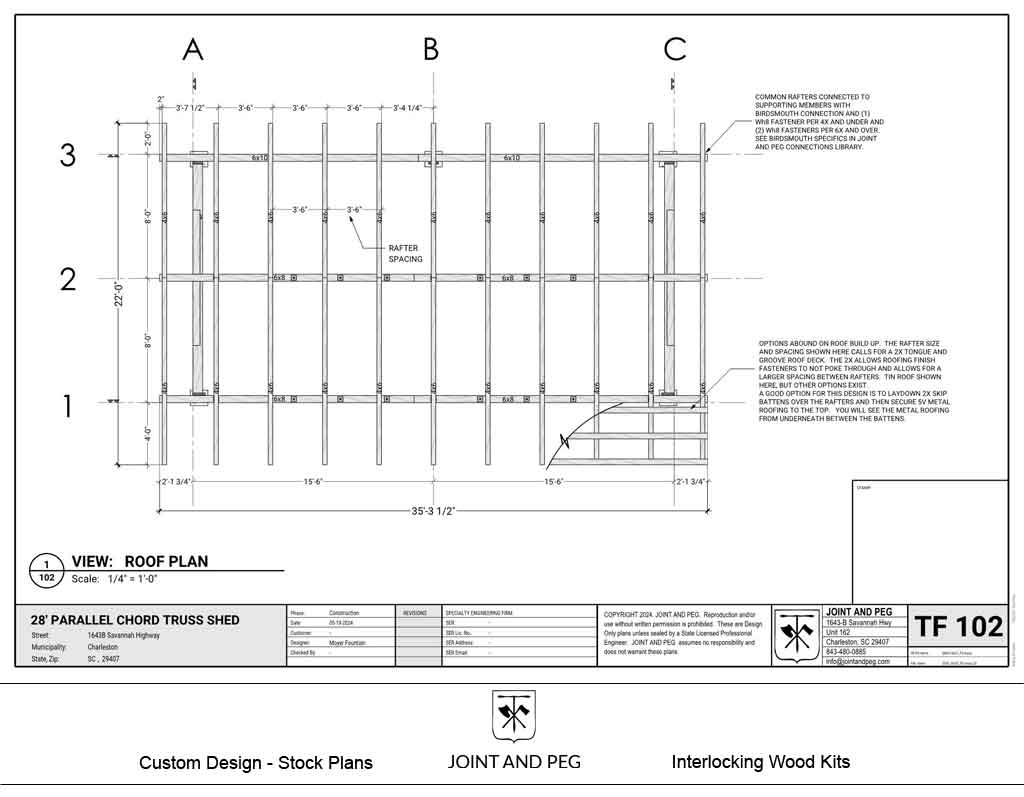

For the roofing we envision 2x skip battens over the rafters allowing you to simply attach metal roofing on top. You could also use a tongue and groove roof deck too if you prefer not to see the metal roofing from below.

Equipment and truck access.

The truss eave measures at 10’ in the clear so that your equipment that you use to load the mill will have access. The gable ends provide 9’ of clearance so that you can pull your full ton truck through to mobilize and return your mill if you travel with it.

Good use of timber materials.

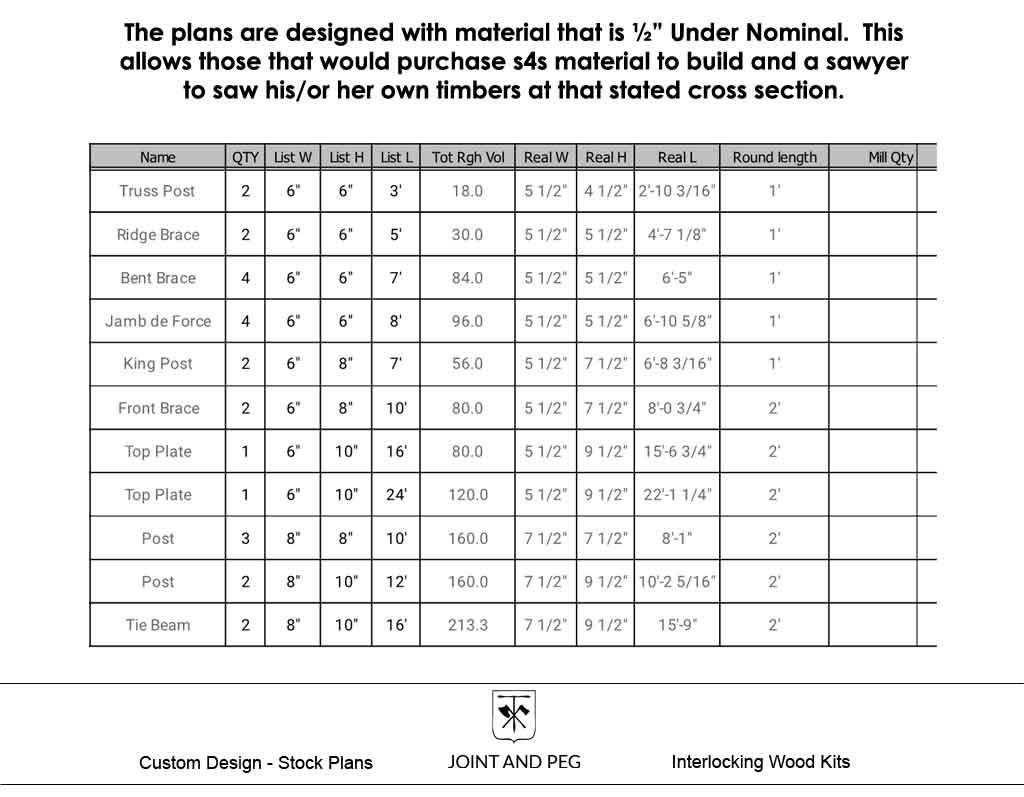

A timber list is provided with this plan requiring 2400 bd/ft of timber to build this structure. These are rough bd/ft needs and if you are sawing your own timber you can count on using less as you don’t need to round up to stock lengths like the list does. The plans are designed with material that is ½” Under Nominal. This allows those that would purchase s4s material to build and a sawyer to saw his/or her own timbers at that stated cross section.

The amount of timber needed is comparable to other sawmill shed plans you can purchase but provides 50% more roof coverage for you and your equipment.

The plan includes options for using glulam timbers for the longest members. These can be purchased from your local lumberyard.

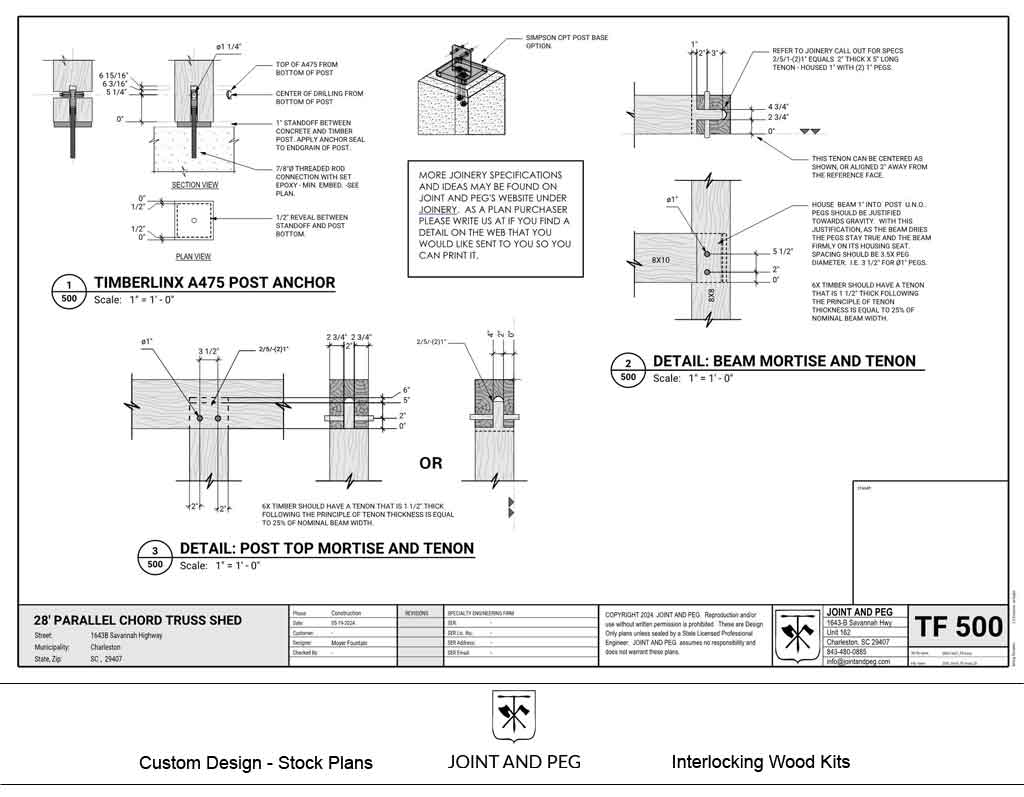

Mortise and tenon joinery.

Plan includes mortise and tenon timber frame design with joinery details so that you can build this in the timber frame style if you like. The parallel chord truss does make use of 5/8” tie rods with square washers, nuts, and screws, but the rest of the structure is mortise and tenon joints with hardwood pegs.

Joint and Peg prides itself on providing the clearest and best joinery detailing available.

Steel connections option.

We do love our joinery but have decided to add some detailing for using steel connectors instead of joinery on this plan. We like this design so much that we wanted to open the doors up to others who may not be tooled up for mortise and tenon joinery.

Specified are L4x4x3/8 angle parts and diagrams on this plan for those that want to build this with utility in mind. 5/8” lag bolts are used. The angle iron is all of the same steel profile. The information is provided so that you can procure exactly what you need from one type of standard steel shape.

You will still be called on to cut housings for bearing, but no mortises, tenons, or pegs.

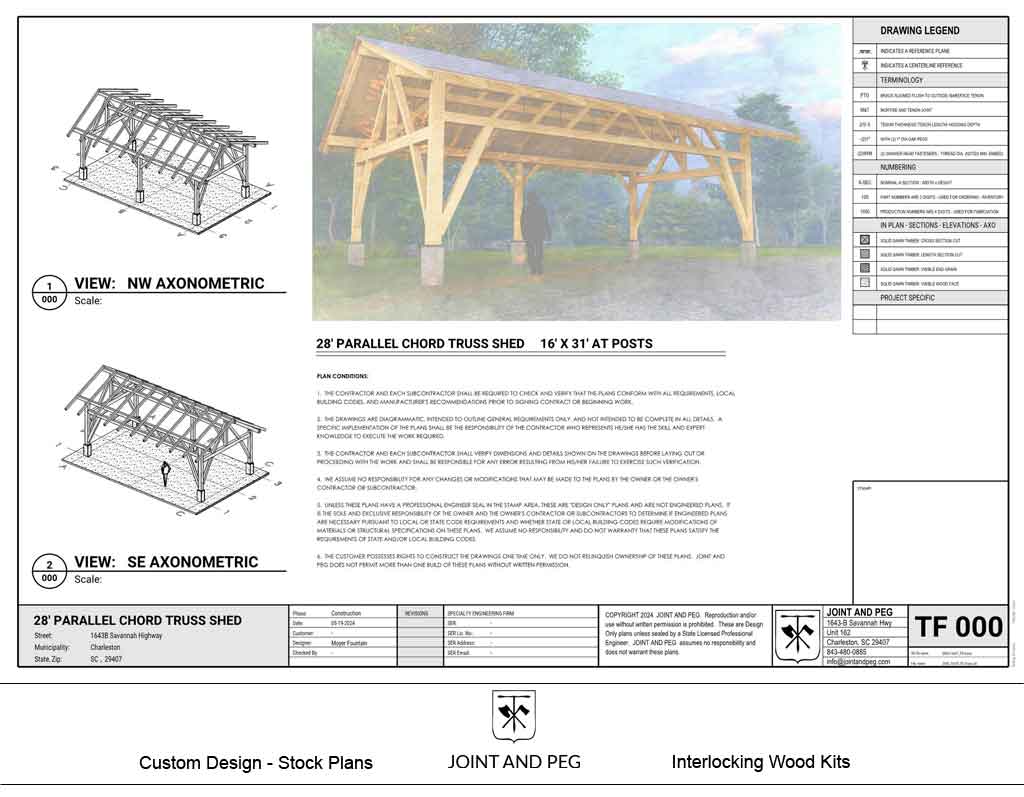

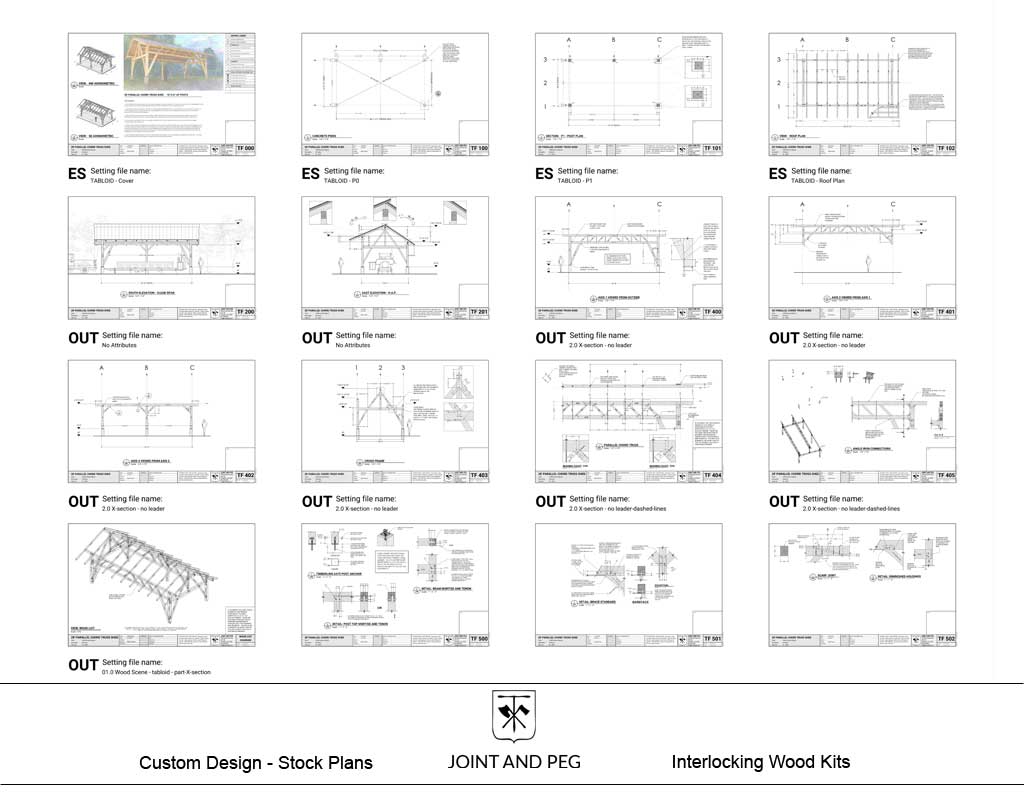

Plan Details

The core plan provides you with all the standard views for construction. This plan is offered in an instantly downloadable .pdf format and includes the following on (16) 11×17 tabloid size sheets:

- Designed with Southern Yellow Pine No. 1 or Douglas Fir No. 1

- Concrete Pier Plan View

- Post Plan View

- Roof Framing Plan View

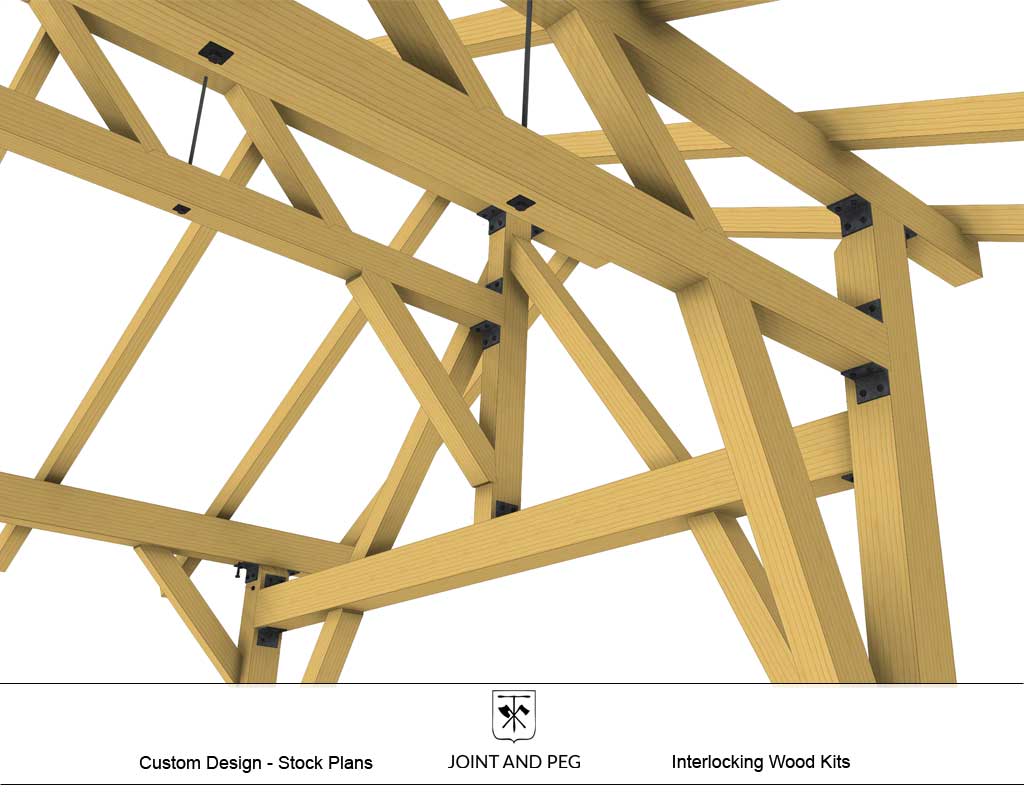

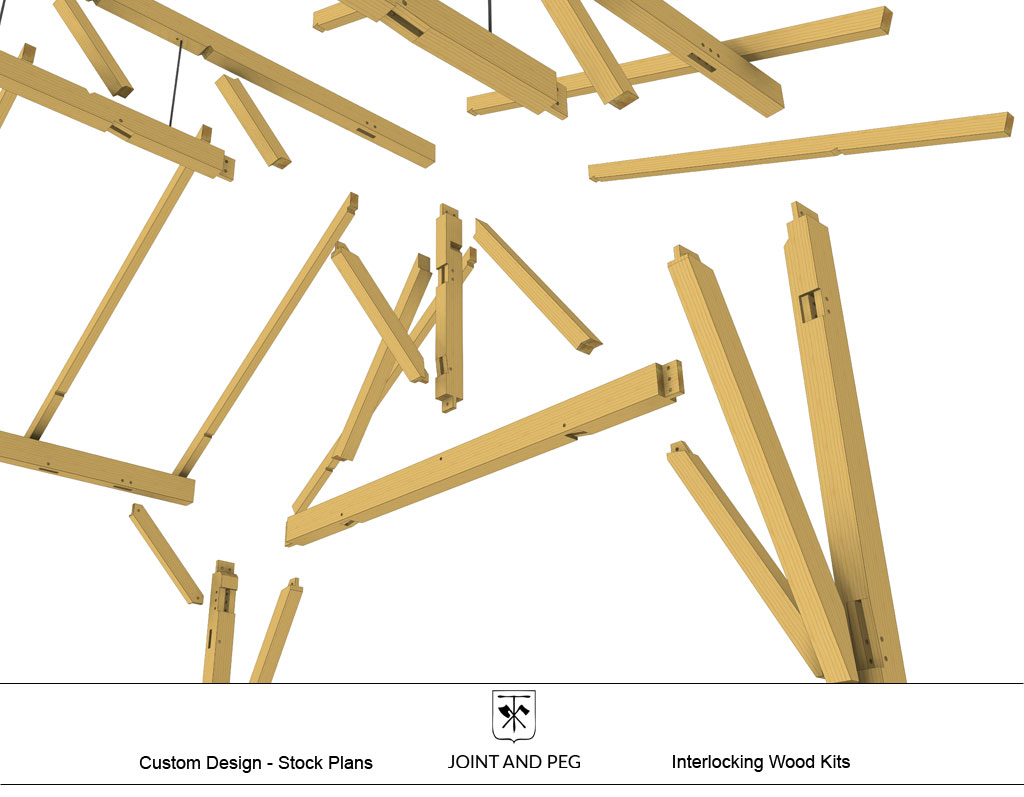

- Axonometric Views

- Wall Frame Elevations

- Cross Frame Elevations

- Parallel Chord Detailing

- Elevation with sawmill in place

- Brace joinery details

- Scarf joint detail

- Diminished housing detail

- Bareface joinery details

- Angle iron details

- Tie rod detailing.

In addition to that, our base plan includes material lists that allow you to easily order and budget for all materials including:

- Timber List: Includes real lengths and rounded lengths that you will use to order materials.

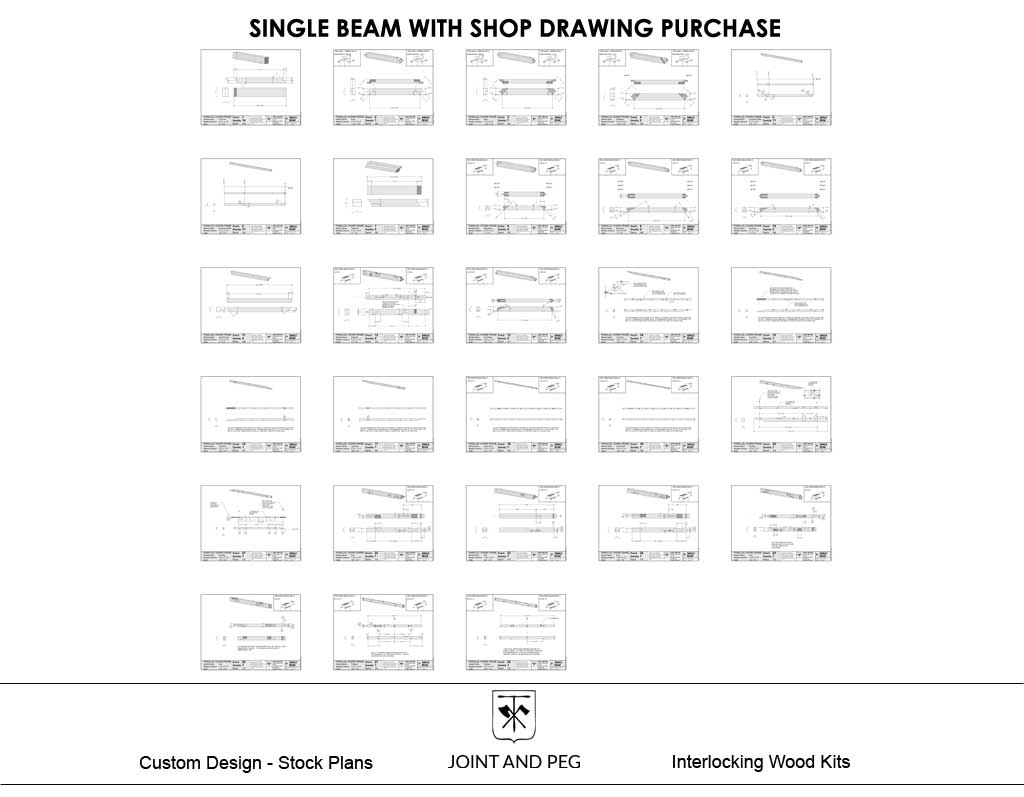

Shop Drawings – Cut Sheets

A purchase of this plan includes individual cut sheets for all the timbers. Each timber is assigned on its own drawing sheet with dimensions to assist in layout of the work. The single beam drawings set for the 16×31 sawmill shed plan includes (30) letter size sheets.

Timber Frame Kit Package

We provide this timber frame structure as a pre-cut ready to assemble kit to the Southeast USA. Please enter your information and we will respond to you with a quote. If you are in our install area we can provide a line item for installation.

Jussi Rasinmäki (verified owner) –

I had been looking for a plan like this for quite a while, and here it is!

I’m feeling quite confident with the provided plan even as a complete timber framing novice. Looking forward to start building.

Also a specific mention for the customer service, which has been super responsive and friendly. I had some detail questions given the location where this will be built.