How to build a timber frame without plywood.

Do you need plywood on your timber frame barn? The short answer is, No. However, it is true that modern day panel products such as OSB and plywood do provide a measure of lateral strength when analyzing enclosed timber frames. In most cases, the desire to build the timber frame without the need for plywood becomes an issue when someone wants to build a timber frame structure that is not insulated. Insulated timber frames typically will have a panel good product as part of the insulating enclosure composition. However, when someone wants to build a true and authentic timber frame barn the last thing they want to do is see plywood from the inside.

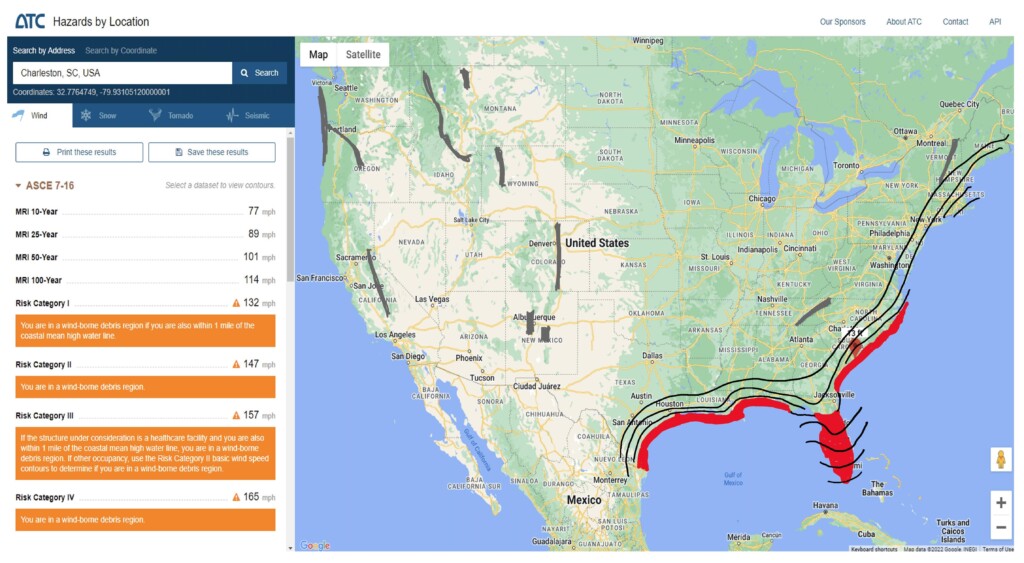

Now it must be considered that different areas of the country will need more lateral stability than others. For instance, along the Gulf Coast and south Atlantic seaboard, timber frames will need to withstand extreme wind loads. Another instance is out West. There is a great deal of seismic zones and areas that will need that additional lateral strength when designing timber frame structures. Relatively milder areas of our country, and continent, might not need the additional lateral strength. In these milder areas, your typical 3′ leg knee braces might be sufficient for lateral strength. Couple them with 4x level girts at 4′ centers, with rough sawn board and batten siding. If this is the case, wonderful; but let’s look at the areas where this girt and siding arrangement will not be adequate.

The High Wind Zones

If wind is a factor in creating stability of your frame design, and you don’t want to use a panel product, what are your options? You should first of all check the loads at your area where you want to build.

Better Bracing

Longer Knee Brace

A typical timber frame knee braces usually has a 3-foot leg in the vertical direction and a 3-foot leg in the horizontal direction. When we need to gain more lateral strength bigger and longer brace members can help. Your typical knee brace only reaches a small portion down or up your post. In order to gain more strength, we need to get at least halfway down, or up, the post. Even better, take a bay and dedicate it to bracing and run the brace more than 50% of the post. Be sure to make sure your post is big enough to withstand the additional bending forces it will be subjected to.

Timber Frame X-bracing

Considering that this brace bay will not be useful for any Rough Openings, I like to go ahead and celebrate it with perhaps some X-bracing. Also called St Andrews Cross this type of configuration can create a much stronger bracing effect. Enough, in most circumstances, to alleviate the plywood in those engineered timber frame drawings. Below is a project that our founder, Moyer Fountain, designed and built that incorporates X-bracing and timber frame stability in a high wind zone, without plywood.

Please contact if you need our expertise. We can get your project going and completed for you.

This timber frame barn was built for a location on the coast. The exposure loads were great considering it is very close to the coast. Designed, Engineered, and Built to withstand 150 mph winds for 3 second gusts. The barn is the monitor style with two flanking sheds on either side of the main frame. There are also two lofts on each end of the frame. The cupolas were also designed and built by us. This frame consists of rough sawn Cypress timber. The structure was built of traditional mortise and tenon joinery with oak pegged connections. Other components in the structure are iron tie rods and X-bracing on the gable ends to withstand the heavy wind loads of the site. We love traditional barns projects!