Brace Joint Details

The timber frame knee brace is an integral part of traditional timber frame construction practice. Also referred to as just a brace, its typically oriented at 45 degrees to the post and beam it connects. The brace works to keep the frame from racking and is an overall fundamental element of a timber frame structure. Braces do not have to be 45 degrees and can sometimes be oriented with more or less slope as aesthetics or structural conditions change. X bracing, which is a favorite of ours, should be considered in this brace classification too.

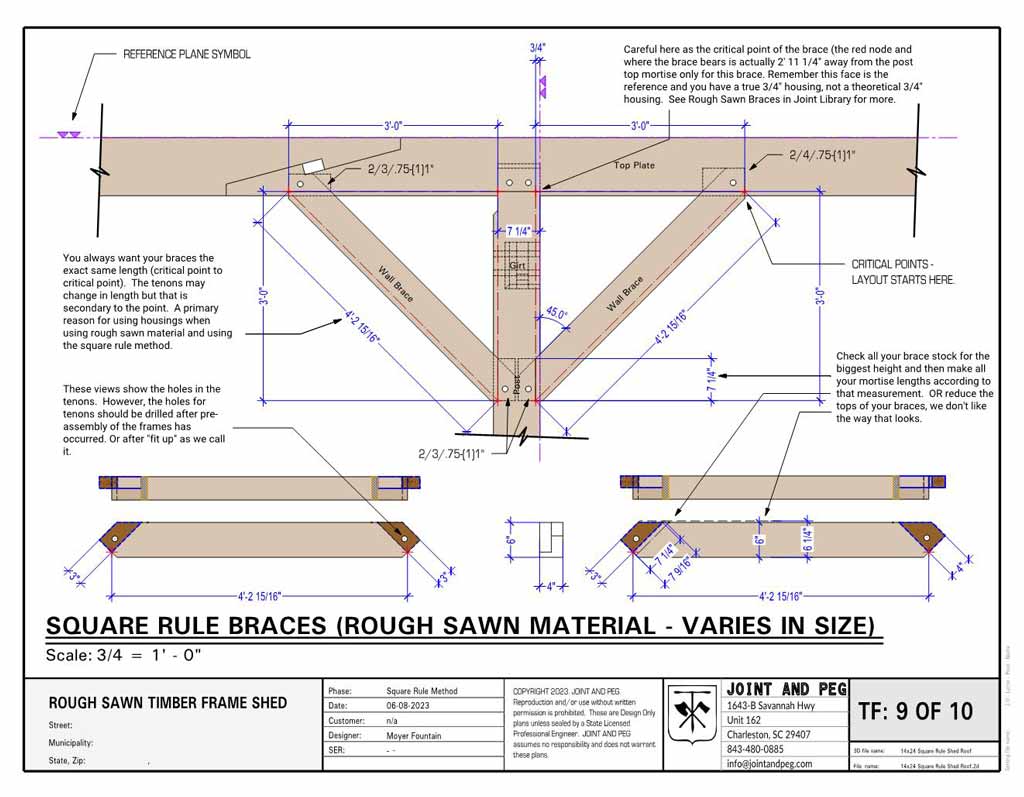

The following details of braces joints should provide you with a good understanding of what these members do and how to go about producing them.

Please see out standard brace drawing before you review the ones that follow.

Table of contents

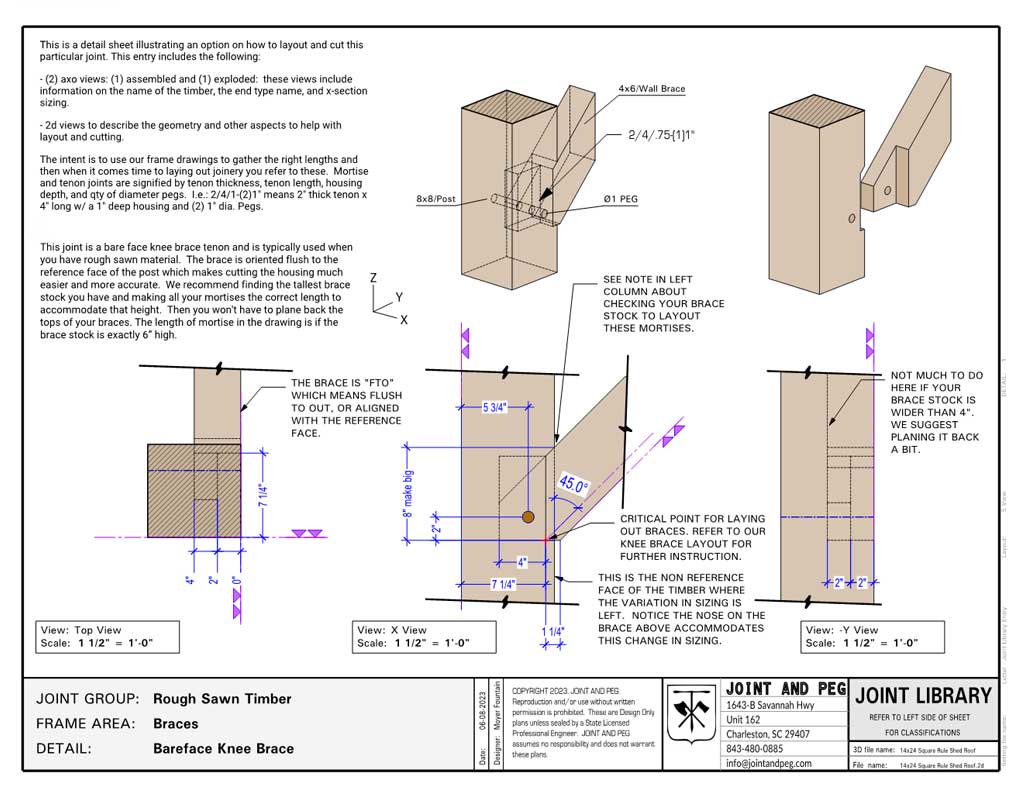

Rough Sawn – 4×6 Bareface Knee Brace

This joint is a bare face knee brace tenon and is typically used when you have rough sawn material. The brace is oriented flush to the reference face of the post which makes cutting the housing much easier and more accurate. We recommend finding the tallest brace stock you have and making all your mortises a corresponding length (usually longer) to accommodate that extra height. Then you won’t have to plane back the tops of your braces. The length of mortise in the drawing is if the brace stock is exactly 6” high.

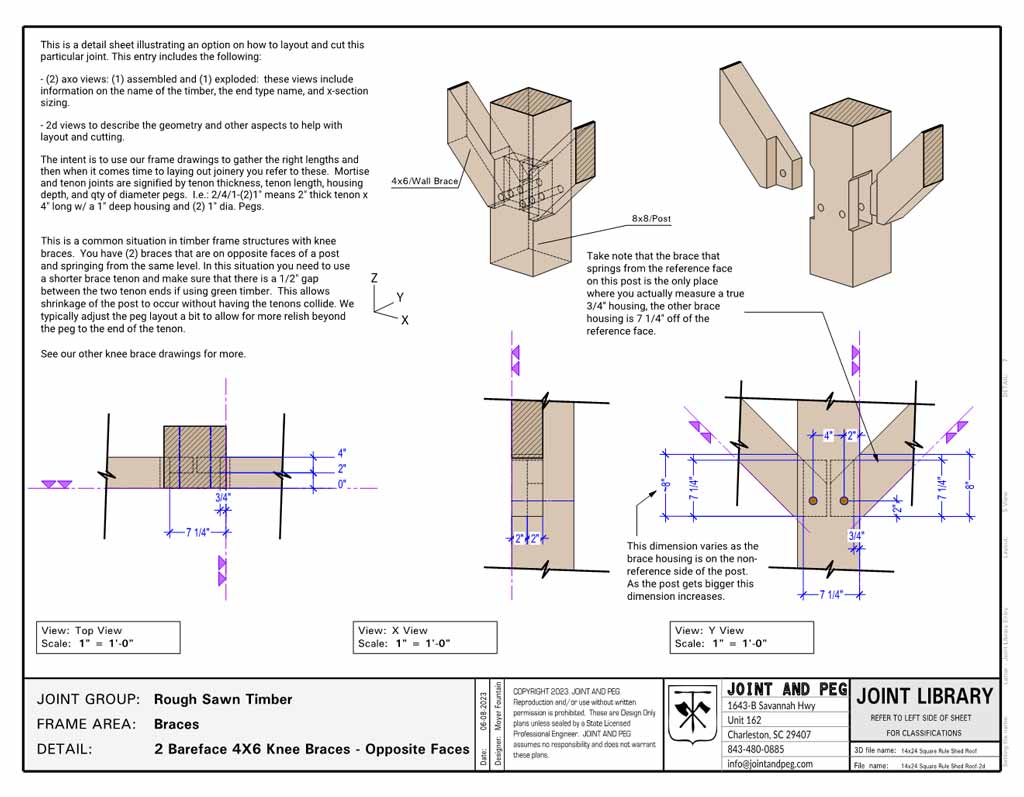

Rough Sawn – 2 Bareface 4×6 Knee Braces on Opposite Faces

This is a common situation in timber frame structures with knee braces. You have (2) braces that are on opposite faces of a post and springing from the same level. In this situation you need to use a shorter brace tenon and make sure that there is a 1/2″ gap between the two tenon ends if using green timber. This allows shrinkage of the post to occur without having the tenons collide. We typically adjust the peg layout a bit to allow for more relish beyond the peg to the end of the tenon.

Timber Frame Joint Details Catalog

Timber frame joint details on (34) individual letter size sheets. All drawings are printable and delivered instantly through a download link. Joint and Peg entries – Volume 1.

Rough Sawn – 8×8 Post, 8×10 Beam, 4×6 Brace Triangle

These components and these instructions make up the crux of building timber frames with square rule joinery. It shows why to lay out a brace from a reference face. The knee braces are always the same length, critical point to critical point, regardless of the length of the tenon on each end. This length realization is an important concept to understand with all brace joinery and timber frame work in general.

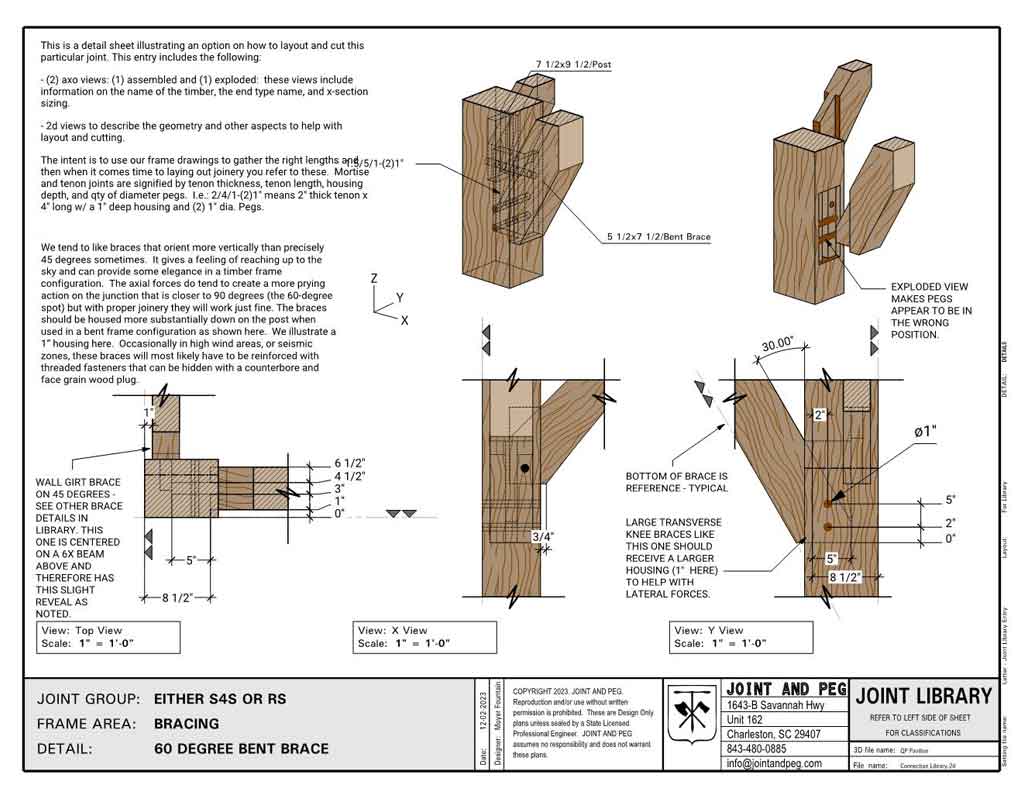

60 Degree Brace – 8×8 post – 6×8 brace

We tend to like braces that orient more vertically than precisely 45 degrees sometimes. It gives a feeling of reaching up to the sky and can provide some elegance in a timber frame configuration. The axial forces do tend to create a more prying action on the junction that is closer to 90 degrees (the 60-degree spot). With proper joinery and timber post and beam sizing they will work just fine.

The braces should be housed more substantially down on the post when used in a bent frame configuration as shown here. We illustrate a 1” housing here. Occasionally in high wind areas, or seismic zones, these braces will most likely have to be reinforced with threaded fasteners that can be hidden with a counterbore and face grain wood plug.